Track shoes and pads introduction:

The rotary drilling rig track shoe is a key load-bearing component of the undercarriage system of a rotary drilling rig. Our pile driving rig track shoes mainly enhances the stability of the contact between the machine and the ground to ensure safe operation under complex working conditions. Pile driving rig track shoes plays an important role in soil drilling, mining, municipal engineering and other fields. We Huayang have focused on the production of pile driving rig track shoes for many years, and through strict quality control, we provide customers with high-reliability and long-life crawler track shoe solutions.

Daily maintenance of pile driving rig track shoes:

1. For pile driving rig track shoes, adjust the tensioning of the track and adjust it according to the tightness of the soil to reduce wear and extend life.

2. During the maintenance of crawler shoes and track pads, check the wearing parts daily: support sprocket, support wheel, drive wheel, rail link, etc. to prevent abnormal wear and tear.

3. Crawler shoes and track pads needs to replace the damaged roller in time to avoid wear and tear of the rail link caused by wear and deviation.

4. Tighten the bolts and nuts, and check the crawler shoes and track pads regularly to prevent loosening from causing the track shoe to break or be damaged.

Featured services:

The crawler shoes and track pads we produce provides customized packaging and multiple transportation options, which meets customer requirements from production to delivery, ensuring safe and efficient delivery of goods.

One-to-one foreign trade managers follow up throughout the process, providing selection, installation and after-sales technical support.

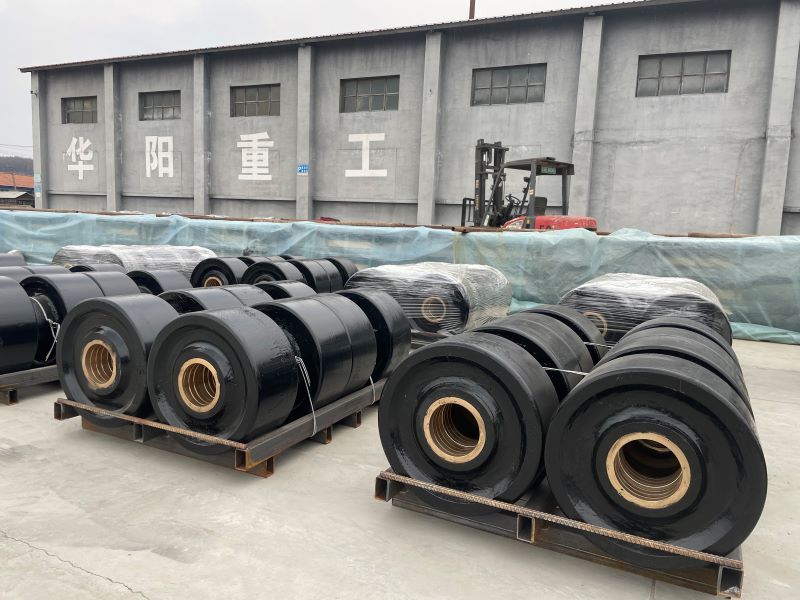

Track shoes and pads packaging:

Most of our track shoes and pads are metal parts, such as heavy-duty parts such as crawler shoes and track pads. If the packaging of the crawler track shoe is not professional, track shoes and pads can easily rust, deform or bump during transportation.

So we pay special attention to packaging, the standards are as follows:

1. For track shoes and pads such as rotary drilling rig track shoe, fumigation-free pallets + packaging film + anti-rust paper + desiccant are used, which are basically standard.

2. Some crawler track shoe customers have higher requirements, so we also provide wooden boxes/steel frame wooden boxes for reinforced packaging.

3. All pallets or boxes will be clearly marked to facilitate receipt and inventory of goods such as crawler track shoe.

4. If there are special packaging requirements for crawler track shoe (such as environmentally friendly materials, logo printing, etc.), we can also customize it.

The goods such as the crawler track shoe we sent out were basically not damaged or rusted during transportation, and customer satisfaction has always been very high.

About us:

Huayang is a modern manufacturing enterprise specializing in the production of crawler track shoe, with a reasonable layout and a fully functional production base. The factory area is planned scientifically, with professional production areas such as raw material storage, precision cutting, heat treatment, machining, spraying and finished track shoes and pads packaging, and a 6S management system is fully implemented to ensure a clean, orderly, safe and efficient production environment.