Product introduction:

Crawler crane top roller is usually composed of a wheel body, bearings, sealing devices, and lubrication systems, which play a key role in supporting the weight of the whole machine and transmitting the driving force. When the equipment is running, the drive wheel drives the crawler crane top roller to rotate through the track. Through contact with the ground, the track roller for crawler crane evenly transmits the weight of the crane to the ground, while pushing the equipment forward or backward smoothly. During operation, the track roller for crawler crane needs to withstand a huge reaction force from the ground, which will be transmitted to the chassis and frame of the crane through the track roller for crawler crane. The entire process guarantees the stability and reliability of track roller for crawler crane in the operation of the equipment.

Performance and process:

Crawler crane track roller is forged as a whole from high-quality alloy steel from large domestic steel companies. The material properties are stable and reliable, it has excellent impact resistance and carrying capacity, and has undergone professional heat treatment technology. The wheel body has high hardness and good wear resistance, which is suitable for frequent heavy-duty operations. Working conditions.

Heat treatment process

Quenching temperature: 850~880℃ (adjusted according to the material), oil-cooled or water-cooled.

Tempering temperature: 400~500℃, eliminate internal stress and balance hardness and toughness.

Surface hardening (optional): High-frequency quenching of the rims, the surface hardness reaches HRC 55~60, and the wear resistance is improved.

Precision machining and testing

CNC CNC machining shaft holes and mounting surfaces, the tolerance is controlled within ±0.1mm, to ensure that the accuracy of the main frame matches.

The whole process of quality inspection includes hardness testing, compression breaking testing and sealing verification.

Our manufacturing advantages:

Our crawler crane track roller uses good alloy steel combined with heat treatment technology to improve the wear resistance of the rims and extend the service life.

Through CNC CNC cutting and processing, the product size is accurate, the edges are flat, and the bearing sealing reliability is guaranteed.

The scientific structural design effectively reduces rolling resistance, makes the crane walk smoother and reduces energy consumption.

Maintenance and maintenance of crawler crane track roller:

Regularly check the sealing device and lubrication system of the crawler crane track roller to ensure its normal operation.

Clean up the dirt and impurities on the surface of the crawler crane track roller in time to prevent it from entering the bearing.

Change the lubricant regularly to ensure the rotation efficiency and life of the crawler crane track roller.

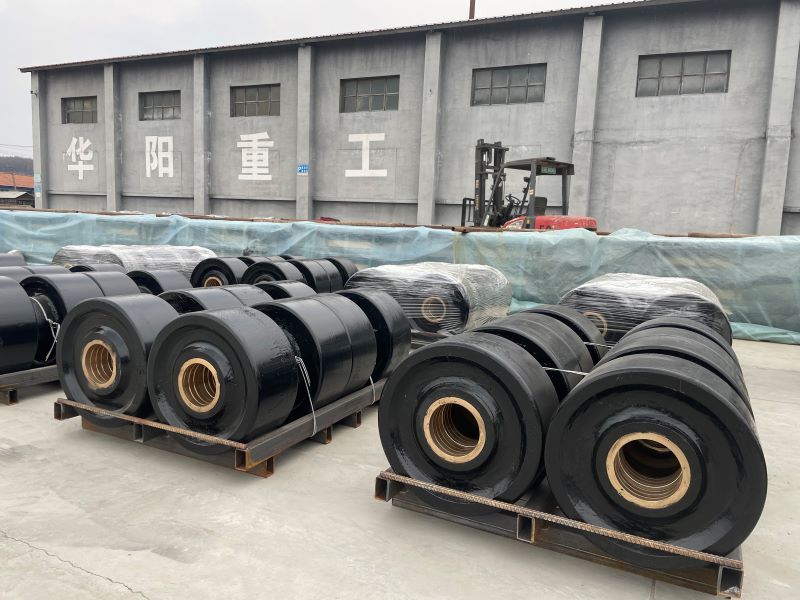

Why do buyers choose us?

Huayang has been deeply engaged in the field of crane track roller manufacturing for many years and understands the needs of end customers.

The use of refined production technology + full-process quality inspection, high consistency of delivered products.

Support special specificationcrane track roller customization, export standard packaging, and stable global delivery.

The technical team is experienced in the industry and has long-term cooperation with a number of companies.

Strictly abide by environmental protection standards and promote green production processes.