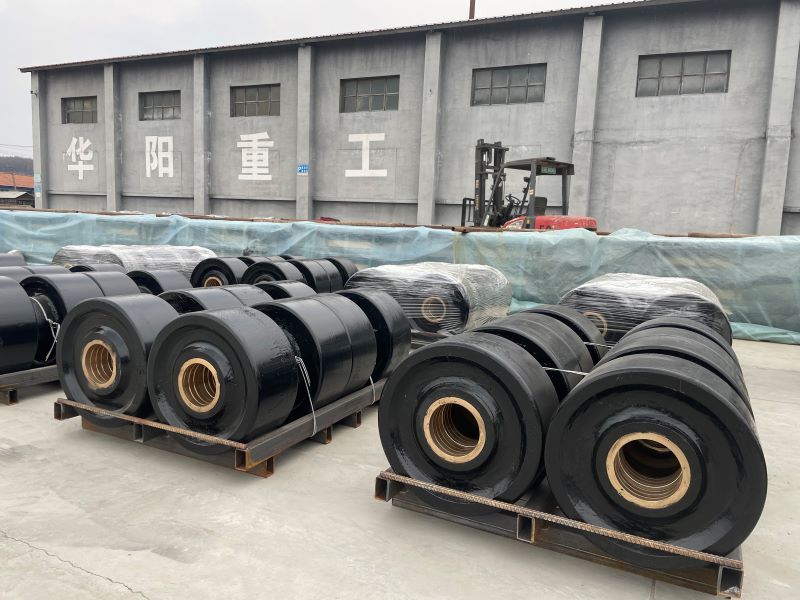

Track rollers for mini excavators introduction:

The working principle of track wheels for excavator is mainly to support the weight of the excavator and allow the track to move along the support wheel. The main components of track wheels for excavator include wheel body, track roller shaft, bushing, etc. Casting excavator track wheel ensure the stability and safety of the excavator when driving on different surfaces by transmitting the weight of the excavator to the ground. Huayang has focused on the production of casting excavator track wheel for many years, providing global construction machinery users with stable performance, high-quality and durable casting excavator track wheel, which are widely used in various heavy-duty environments, such as construction, bridges, water conservancy, energy and port engineering.

Advantages of casting excavator track wheel:

1. All casting excavator track wheel have passed strict quality control processes such as dimensional inspection, hardness testing, and hole deviation inspection to ensure the reliable quality of each excavator track roller.

2. We provide OEM and customized processing services for casting excavator track wheel. You can send drawings or specifications. We are experienced in the customized production of excavator track rollers and can flexibly meet your unique needs to create excavator track rollers that meet your requirements.

3. We provide one-stop service for excavator bottom roller. From selection consulting, technology matching to logistics and distribution, we provide worry-free supply chain solutions to help customers efficiently complete the procurement needs of excavator bottom roller.

Performance and construction of track wheels for excavators:

1. Excavator track rollers utilize high-strength alloy plates supplied by major domestic steel companies. This material offers stable quality, excellent mechanical properties, and metallurgical consistency, making them suitable for frequent load and impact scenarios.

2. Construction of excavator bottom rollers:

Normalizing: Eliminates internal stresses in the material and prevents post-processing deformation.

Quenching: Increases metal hardness and strength, enhancing wear resistance.

Tempering: Improves metal toughness, prevents cracking, and maintains a balance between load-bearing capacity and impact resistance.

After heat treatment, the hardness of the track rollers for mini excavators is controlled within the HRC42-55 range, ensuring sufficient strength without being too hard and prone to brittle cracking.

Daily maintenance of excavator bottom roller:

1. Avoid long-term soaking of excavator bottom roller: During the work process, try to prevent excavator bottom roller from being soaked in mud and water for a long time, and reduce the erosion of excavator bottom roller and related components by mud and water.

2. Daily cleaning and treatment: After the work is over every day, the excavator needs to be propped up on one side of the track, and then the walking motor is driven. The rotation of the track is used to get rid of the dirt, gravel and other debris attached to the track, and keep the excavator track rollers and the surrounding area of the track clean.

3. Moisture-proof protection in winter: During construction in winter, be sure to keep excavator track rollers dry.Since there is a floating seal between the outer wheel and the shaft of the excavator track rollers, if there is moisture residue, ice will form at night. When the excavator is moved during the operation the next day, the seal is easily scratched in contact with the ice, which can easily cause the excavator track rollers to leak oil.

About Us

Huayang has been deeply engaged in the field of heavy machinery and equipment for many years, and is familiar with the structure and use of various support wheels and other products. Track rollers for mini excavators can provide professional matching suggestions according to the different models and working conditions of customers, whether track rollers for mini excavators is the rapid large-scale shipment of conventional styles or the customized requirements of special specifications, track rollers for mini excavators can respond quickly and efficiently. In addition, we have long-term supporting cooperation experience with a number of oems, have a deep understanding of the actual assembly situation, and have accumulated a wealth of first-line adaptation feedback, which can provide you with more practical products and professional suggestions. We look forward to working with you hand in hand to provide strong support for your business development.