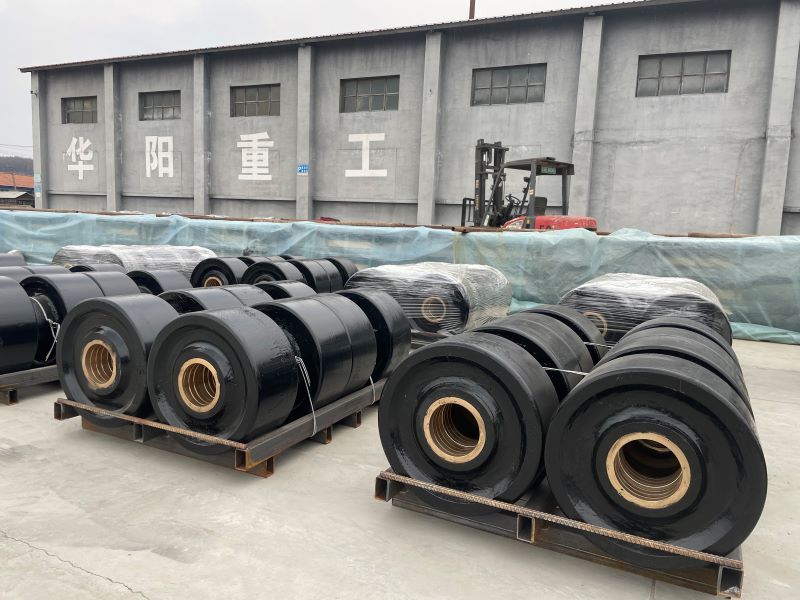

Product introduction:

Wheel bulldozer guide wheel is the core component of the bulldozer track system, which is mainly responsible for accurately guiding the track movement and preventing derailment. Our bulldozer front and rear guide wheel significantly improves operation stability and driving comfort by providing stable support and shock absorption. The bulldozer front and rear guide wheel we designed can effectively reduce friction and wear, and extend the service life and maintenance cycle of equipment. Our bulldozer front and rear guide wheel enables bulldozers to operate efficiently and improve overall performance. The structure of the bulldozer front and rear guide wheel is sturdy and durable, and bulldozer guide wheel is easy to maintain. This bulldozer track guide wheel maintains reliability in harsh environments and is an indispensable key component of bulldozers.

Application scenario:

In the foundation construction of high-rise buildings, the bulldozer track guide wheel usually accurately guides the track system to effectively prevent the risk of derailment caused by soft soil. Our bulldozer track guide wheel adopts a special shock-absorbing structure that can absorb more than 30% of the impact load, ensuring that the bulldozer idler equipment can operate continuously for more than 8 hours on construction sites full of steel bars and debris.

In mining scenarios, facing 45-degree steep slopes and gravel environments, our bulldozer track guide wheel adopts reinforced alloy rim design, and its unique self-cleaning groove can automatically discharge ore debris. Our wheel bulldozer guide wheel is equipped with a temperature-controlled bearing system, which allows our bulldozer track guide wheel to maintain stable performance under continuous heavy-duty conditions and reduce the equipment failure rate.

During asphalt laying operations, the bulldozer idler realizes precise steering control of ±2°, and the nano-coating technology on the surface of the bulldozer idler reduces the coefficient of friction by 40%. The special sealing structure of our bulldozer idler can effectively isolate the intrusion of sand and dust, and extend the maintenance cycle by up to 50% in highway renovation and expansion projects.

For muddy areas, our bulldozer idler adopts a widened wheel surface design (1.5 times the width of the standard type), combined with an anti-winding convex tooth structure. The multi-stage buffer device of our bulldozer idler can be adapted to irregular obstacles such as tree roots, and the passability can be improved by more than 30% in rainforest reclamation.

Our bulldozer idler provides all-weather protection for construction machinery through scenario-based innovative design.

Advantages of bulldozer guide wheel:

1. We provide customized services for guide wheels for customers in many countries around the world, and provide technical information on guide wheels to help customers efficiently maintain and upgrade.

2. Through three-dimensional modeling and data analysis of the original vehicle, the hole pitch, thickness, and matching size of each guide wheel can be perfectly matched with the vehicle, making high-precision installation and stable operation of the equipment.

About us:

We offer OEM and custom fabrication services. Simply send us your drawings or specifications for products like the Bulldozer Idler, and we'll handle everything from material selection to final delivery. We have extensive experience in custom manufacturing and are flexible enough to meet your unique needs. So, what makes us so confident? It's the dedicated and capable team behind us.

We're proud of our growing team of engineers, technicians, and trade professionals who bring a wealth of experience and passion to every project. We firmly believe that practical expertise, responsiveness, and attention to detail are key to earning our customers' trust.