Excavator drive sprocket introduction:

The excavator sprocket wheel is usually located at the rear of the excavator walking device. The working principle is that the power of the engine is transmitted to the track through the walking motor and the excavator sprocket wheel. It is required that the excavator sprocket wheel engages with the track chain of the track correctly, and the transmission is stable, and when the track is stretched due to the wear of the pin sleeve, the driving wheel for excavator can still engage well.

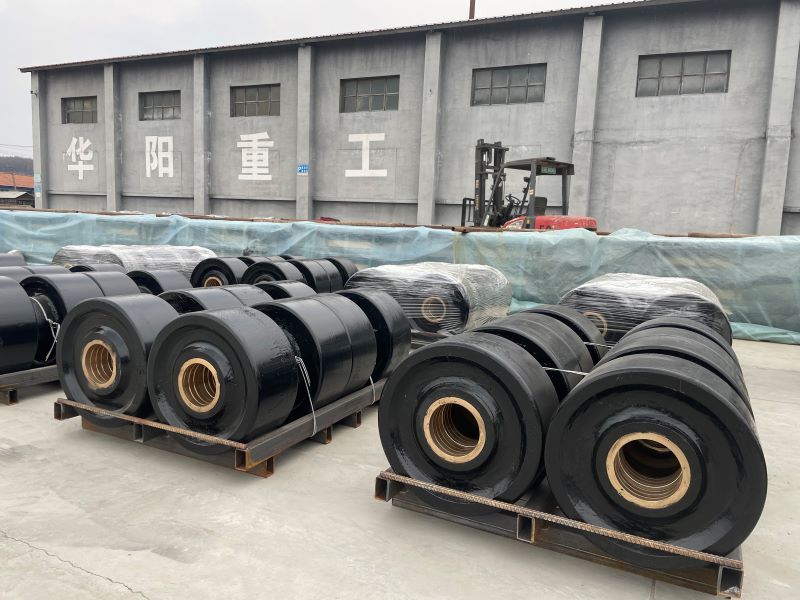

Excavator sprocket wheel is mainly composed of gears, wheels, bearings and other components, and excavator drive sprocket structure is relatively simple. Excavator sprocket wheel has high transmission efficiency and can reduce energy loss. Driving wheel for excavator can withstand large loads and is suitable for heavy excavators. The driving wheel for excavator is easy to maintain and easy to replace worn parts.

Performance and craftsmanship of excavator drive wheel:

1. Excavator drive wheel adopts high-strength alloy sheet provided by large domestic steel companies. The material quality is stable, with good tensile strength and impact toughness, and excavator drive sprocket is suitable for frequent start-stop and heavy-duty impact conditions of excavators.

2. Heat treatment process

Annealing: Heating to above the critical temperature, slowly cooling, eliminating internal stress, improving processing performance, and homogenizing the organization of castings. Normalizing: Air cooling after heating to refine the grain and improve the comprehensive mechanical properties of the material.

Quenching: Rapid cooling to form a high hardness martensitic.

Tempering: Reheat to low temperature after quenching to reduce brittleness and balance strength and toughness.

3. Machining accuracy and inspection:

Cutting method: Cnc plasma cutting is used to ensure that the contour of the wheel billet is flat and there are no burrs.

Mechanical properties testing: Use CSS44300 universal tensile testing machine for tensile, compressive, fatigue and other performance testing.

Dimensional control: The use of CNC machining centers to ensure the high precision of hole spacing, thickness and mating position, so that the excavator drive sprocket is seamlessly connected to the original parts.

Provide services:

1. The driving wheel for excavator we excavator drive sprocket can be customized with non-standard drawings according to different brands, models and project needs.

2. All our excavator drive wheels have passed strict quality control processes such as chemical composition analysis, hardness testing, metallographic inspection, and hole deviation inspection.

3. The one-to-one follow-up foreign trade manager connects the whole process to provide excavator drive wheel with a perfect after-sales service guarantee.

Why do buyers choose us?

We have rich international service experience and understand the needs of end customers.

Our product models are suitable for more than 100 brands, with sufficient production capacity, punctual delivery, and efficient inventory management.

We support a variety of flexible settlement methods such as T/T and Western Union, one-to-one connection throughout the process, and quick after-sales response.

Using precision-controlled heat treatment + complete testing process, the delivered excavator drive sprocket have high consistency.

Our driving wheel for excavator is cost-effective and can be flexibly customized according to customer needs.