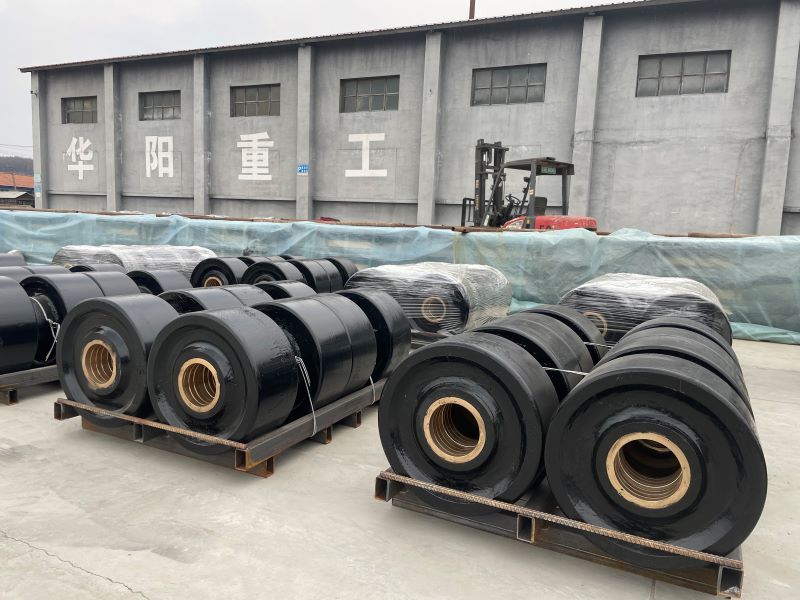

Product introduction:

Carrier roller for excavator is the core component in the excavator crawler system, designed for efficient power transmission. Our excavator carrier roller for excavator is made of high-strength alloy material, which can withstand heavy-duty shocks and ensure the smooth operation of the track. The carrier roller for excavator has a simple structure, which is easy for daily maintenance and replacement, and can reduce the risk of downtime. The durability of our carrier roller for excavator extends the life of the equipment and improves operational efficiency. Undercarriage carrier rollers is a key component for excavator performance enhancement and provides reliable support.

Manufacturing process:

Our undercarriage carrier rollers uses high-strength alloy steel materials to strengthen the mold structure through fully automatic closed forging and forming technology to solve the folding defects of forgings.

We pass the heat treatment stage, including residual temperature normalizing treatment to improve the strength and bearing capacity of the undercarriage carrier rollers, and induction hardening treatment of the tread to enhance the wear resistance of the undercarriage carrier rollers. According to different working conditions, our carrier roller is designed as a variety of structures such as “F” type and “T” type (support customization) to meet the needs of the host. The assembly process includes bearing installation to ensure the smooth operation of the carrier roller. The carrier roller we manufacture has high durability and easy maintenance characteristics, and is suitable for heavy-duty environments. The overall process of our carrier roller improves the reliability and life of the track system.

Our service:

1. The excavator carrier roller we produce can be customized with non-standard drawing paper according to different brands, different models, and different project needs.

2. All excavator carrier rollers have undergone strict quality control processes such as chemical composition analysis, hardness testing, metallographic inspection, and tensile testing.

3. We also provide OEM and customized processing services. You can send drawings or specifications, and we will handle the follow-up from material selection to final delivery. We are experienced in customized production and have the flexibility to meet your unique needs.

Why do buyers choose us?

1. We have an independent production base and advanced equipment specially designed for carrier roller, and implement a 6S management system to ensure that the quality of excavator carrier top roller is controllable throughout the process.

2. We are familiar with the structure and use of excavator carrier top roller, and can provide professional matching suggestions according to customer models and working conditions.

3. Our excavator carrier top roller adopts precision-controlled heat treatment and a complete inspection process to achieve highly consistent delivery.

4. Excavator carrier top roller can be shipped in major ports in China according to demand to ensure punctual delivery.

5. We have rich international service experience and provide excavator carrier top roller solutions and related technical information to customers around the world.