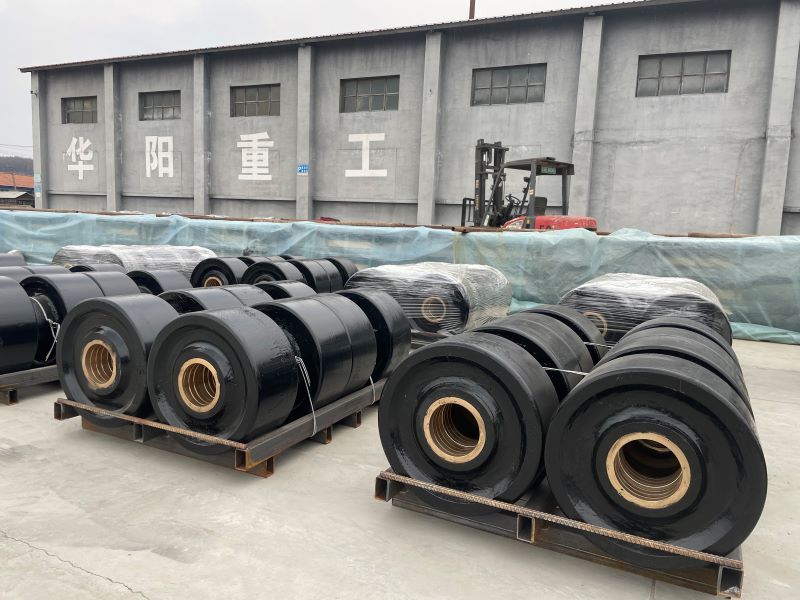

Product introduction:

In the wear-resistant rotary drilling rig track roller, the wear-resistant rotary drilling rig track roller is a key component used to support the rotary drilling rig to withstand huge pressure during operation. The working principle of wear-resistant rotary drilling rig track roller is: When the rotary excavator is started, the drive wheel drives the support wheel to rotate through the crawler. In wear-resistant rotary drilling rig track roller, the support wheel transmits the weight of the equipment to the ground through contact with the ground, while pushing the equipment forward or backward. During operation, the track roller for bored pile requires the support wheel to withstand the reaction force from the ground, and this force will be transmitted to the chassis and frame of the rotary excavator through the support wheel. Therefore, the design of the track roller for bored pile must have sufficient strength and stability to make the entire system operate efficiently. Strengthening the track roller for bored pile is the key to improving the performance of the equipment, and the stability of the track roller for bored pile directly affects the safety of the operation.

Provide services:

1. The track roller for bored pile we produce can provide non-standard drawing customization services according to different brands, models and project needs, so that the rotary drilling rig track roller can be adapted to your rotary excavator.

2. All track roller for bored pile have passed strict quality control processes such as chemical composition analysis, hardness testing, metallographic inspection, and tensile testing to ensure the reliability of rotary drilling rig track rollers.

3. For track roller for piling rig orders, we will arrange a one-to-one follow-up foreign trade manager to connect the whole process to ensure that every link from order confirmation to delivery is efficient and transparent.

4. Track roller for piling rig can be shipped from major ports in China according to customer needs to guarantee the delivery date.

Daily maintenance:

1. Clean the surface of the track roller for piling rig regularly to avoid wear caused by the accumulation of mud, water and gravel.

2. Regularly fill with lubricating oil to maintain the normal operation of the lubrication system and extend the service life of the track roller for piling rig.

3. Check whether the seals and bolts of the track roller for piling rig are intact, and replace the damaged parts of the track roller for piling rig in time.

4. Avoid frequent steering of the track roller for piling rig on inclined or hard ground, and reduce abnormal wear and tear of the track roller for bored pile.

Our manufacturing advantages:

1. The production and manufacturing of rotary drilling rig track roller strictly implements 6S management, and comprehensive testing from raw materials to finished products to ensure stable and reliable quality.

2. We are experienced and have international service capabilities, supplying customers in many countries around the world, and providing relevant technical information.

3. We introduce low-energy and low-emission equipment, promote green production processes, and give priority to the use of environmentally friendly materials to reduce the impact on the environment.

About us:

Huayang is a company focused on heavy machinery and equipment manufacturing, providing a full range of services from OEM customization to mass production. We have a modern smart factory, equipped with industry-leading processing equipment and advanced digital management system, and strictly follow the ISO quality management system. With many years of industry experience and technology accumulation, we have established long-term cooperative relations with many well-known customers, and our products are widely used in many fields such as energy, mining, and infrastructure. We look forward to working with you hand in hand to provide strong support for your business development.