Introduction of excavator guide roller wheel:

Steel excavator guide wheels are core components of the crawler excavator's travel system, primarily consisting of a wheel body, bearing housing, floating seal ring, lubrication system, and fasteners. The wheel body of steel excavator guide wheel is primarily cast or forged from high-strength alloy steel, with a hardened surface for enhanced wear resistance. Internally, they are supported by spherical roller bearings and feature floating seals to prevent mud and sand intrusion. The steel excavator guide wheel works by meshing with the track shoe to transmit driving force, while guiding the track to maintain a stable running track and bearing the weight of the excavator and impact loads during operation. Excavator guide roller wheels are widely used in mining, port loading and unloading, municipal engineering, and field construction.

Excavator chassis guide wheel processing process:

We utilize a "standard process + key process enhancement" model to control every process detail from the source:

1. Raw Material Inspection: Excavator chassis guide wheels are made of high-quality high-manganese steel or wear-resistant plates, and undergo chemical composition and hardness testing before entering the factory.

2. Precision cutting of excavator front track guide wheel: CNC cutting ensures accurate, uniform dimensions and neat edges for each plate.

3. High-Frequency Heat Treatment: Specific heat treatment parameters are selected for the different operating conditions of the excavator chassis guide wheel to enhance wear resistance.

4. Machining: All screw holes and mounting holes are CNC machined to ensure no deviation from the overall machine.

5. Assembly Inspection: Some excavator chassis guide wheel components undergo pre-assembly inspection to ensure efficient assembly.

6. Surface Treatment and Painting: Anti-rust paint or customer-specified color spraying is used to meet export packaging standards.

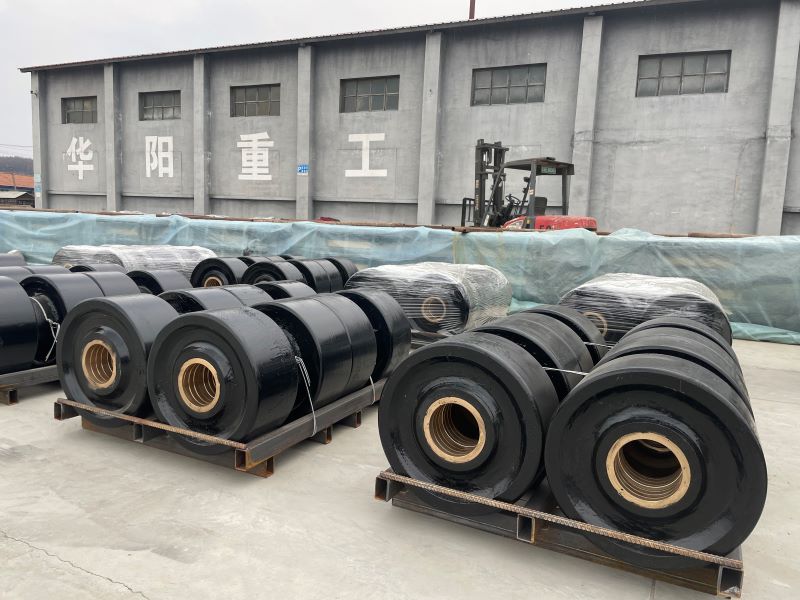

7. Cleaning, Packaging, and Storage: The final excavator front track guide wheels are cleaned and rust-proofed by a dedicated technician before being packaged and stored for shipment.

FAQ of excavator chassis front guide wheels:

1. Is there a minimum order quantity requirement for excavator chassis front guide wheels?

We are flexible about minimum order quantities, depending on the type of excavator front track guide wheels and project requirements. For first-time customers, we welcome small trial orders to verify product quality and workmanship.

2. How do we guarantee the quality of steel excavator guide wheel?

We strictly adhere to the ISO9001 quality management system and implement full-process quality control. Every batch of excavator chassis front guide wheels passes quality inspection before shipment, ensuring 100% qualified product delivery. We are confident in the quality of excavator front track guide wheels and provide long-term technical support and after-sales guarantee.

About Us

Huayang is a comprehensive supplier specializing in the research, development, manufacturing, and sales of heavy industrial equipment, mining machinery, and key components. Over the years, our steel excavator guide wheels have been widely used in a variety of industries, including mining, construction, and energy. We not only provide standardized equipment, but also offer customized excavator chassis front guide wheel. We are committed to becoming your trusted, long-term partner in China.