Introduction of gear crawler crane drive wheel:

Gear crawler crane drive wheels are the load-bearing wheels that directly contact the rails in a crane's trolley or carriage travel system. Made from forged steel, these wheels undergo quenching and other heat treatments to enhance wear resistance. They primarily consist of a rim, tread (the surface in contact with the rails), and hub. Huayang has specialized in the production of gear crawler crane drive wheels for many years, providing global construction machinery users with high-performance, highly compatible gear crawler crane drive wheels suitable for a wide range of heavy-duty applications, including those in construction, bridge construction, water conservancy, energy, and port engineering. We offer standardized gear crawler crane drive wheels and also accept OEM/ODM customization services, adapting to many major international brands and models.

Main application scenarios and advantages of crawler crane wheels:

| Scenario type | Core advantages of crawler crane wheels | Typical operating conditions |

| Container handling at ports | Extremely high wear resistance, suitable for frequent starts and stops | High salt spray, humid environments |

| Heavy lifting at construction sites | Shock load resistance, stable operation | Complex terrain, high-load operations |

| Travel systems for mining equipment | Dust-proof seal design, extended service life | Dusty, high-impact environments |

Daily maintenance of crawler crane wheels:

1. Regular inspection:

Inspect the wheel tread for wear, cracks, or deformation to ensure the wheels are free of abnormalities.

Check the condition of the bearings and lubrication system of the crawler crane wheels to prevent oil depletion or damage.

2. Lubrication maintenance:

Add grease (rolling bearings) or lubricating oil (sliding bearings) according to specifications to ensure adequate lubrication.

Clean the crawler crane wheels of oil and impurities to keep the lubrication system clean.

3. Tightening and adjustment:

Check the bolts and shaft end fasteners of the crawler crane wheels for looseness and tighten them promptly.

When adjusting the gear crane wheel, avoid eccentric wear or abnormal stress.

4. Cleaning and protection:

Remove oil, metal shavings, and other debris from the wheel tread of the crawler crane wheels.

When used in a corrosive environment, the gear crane wheel needs to be regularly treated with anti-rust treatment.

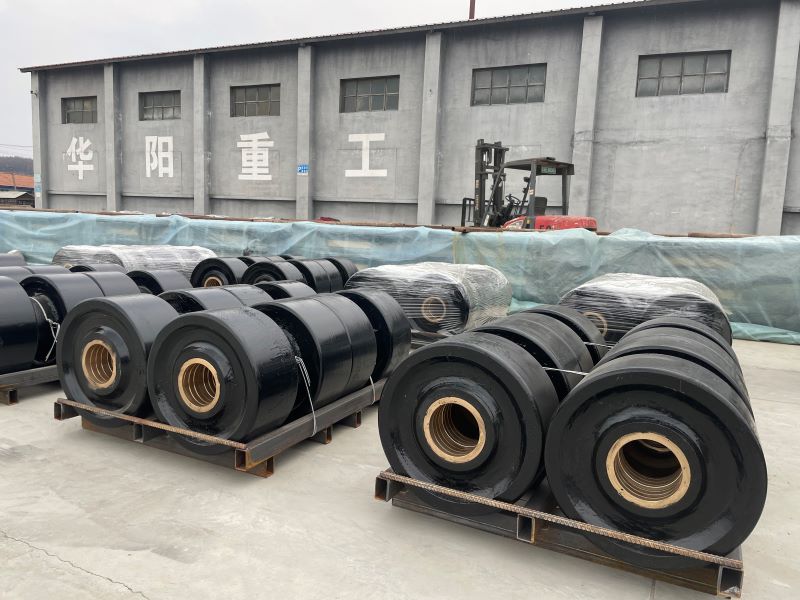

About Us

Huayang is a high-tech enterprise specializing in the research, development, manufacturing, and sales of heavy industrial equipment and key components. With a modern production base and advanced equipment, we rigorously control every production process, from raw materials to finished product, to ensure the consistent and reliable quality of our gear crane wheels. We offer professional logistics and transportation solutions and damage-resistant packaging services, covering shipping to major ports worldwide. Adhering to the philosophy of green production, our gear crane wheels utilize environmentally friendly processes and materials, actively fulfilling our corporate social responsibility. With an experienced and professional team and one-on-one service throughout the entire process, we are committed to providing our customers with high-quality gear crane wheels and reliable service. We look forward to establishing long-term partnerships with you.