Product introduction:

The rotary drilling rig carrier roller is located above the X frame of the crawler frame of the rotary drilling rig. The main role of carrier roller for rotary drilling rig is to support the upper part of the track chain rail, prevent it from sagging or shifting, and ensure that the track maintains linear motion when walking. If the carrier roller for rotary drilling rig is damaged, the track may not be able to walk in a straight line, affecting the stability and work efficiency of the equipment. Carrier roller for rotary drilling rig also reduces the sliding friction between the track and the track frame through rolling contact and extends the life of the track. Carrier roller for rotary drilling rig also disperses the local pressure of the weight of the equipment on the track. The overall design of rotary drilling rig track roller guarantees the efficient operation of the equipment. Rotary drilling rig track roller needs to focus on daily maintenance to avoid potential failures.

Performance and process:

1. Our rotary drilling rig track roller adopts high-strength alloy sheets provided by large domestic steel companies. The material quality is stable, with good mechanical properties and metallurgical consistency, and it is suitable for carrier rollers in frequent load impact scenarios.

2. In the machining process of rotary drilling rig track roller, all screw holes and mounting holes are CNC machined to ensure that the carrier roller has no deviation from the whole machine.

3. The heat treatment process of our undercarriage carrier rollers includes high-frequency surface quenching treatment to enhance the rim hardness of the undercarriage carrier rollers.

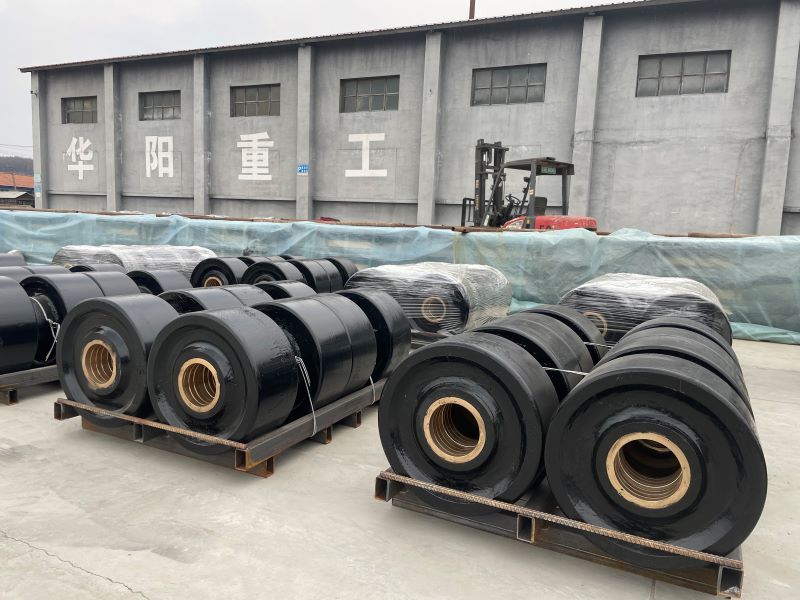

4. Carrier roller adopts press-mounted bearings, infuses grease into undercarriage carrier rollers, installs seals, and finally performs anti-rust spraying.

Daily maintenance of undercarriage carrier rollers:

Regularly clean up the soil and gravel accumulated on the slope of the X-frame to avoid obstructing the rotation of the undercarriage carrier rollers.

Check the fastening status of the bolts and whether there are signs of oil leakage.

Avoid soaking the undercarriage carrier rollers in mud and water for a long time. If an oil leak is found, a new wheel body needs to be replaced in time.

Alternately adjust the walking direction to avoid excessive force on one side of the carrier roller caused by long-term one-way driving.

About us:

Huayang is a heavy machinery parts manufacturing enterprise integrating R&D, production and sales, focusing on providing global customers with high-wear-resistant carrier roller and other construction machinery parts. We have a modern production base, equipped with advanced equipment such as CNC cutting, high-frequency quenching, and automated spraying, with an annual production capacity of one million pieces, which can meet large-volume orders and urgent needs. In terms of services, we provide one-stop solutions from material selection to logistics and transportation, support various modes of transportation such as sea, rail, and air transportation, and use customized packaging to ensure zero loss of goods. With a strict 6S management system and a multi-link quality inspection process, we ensure that every product meets international standards. Huayang insists on taking customers as the center, providing flexible payment, full tracking and rapid response services, while practicing the concept of green manufacturing and contributing to sustainable development. No matter where you are, we can become your trusted partner and look forward to cooperating with you!