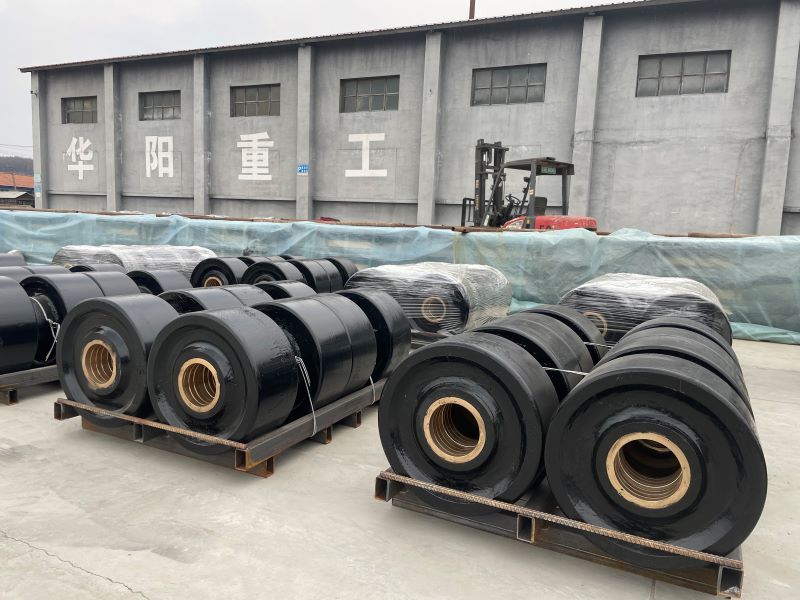

Crawler drive wheel for bulldozer introduction:

The forged bulldozer drive wheel(forged drive wheel for mining) is the core component of the bulldozer, which is responsible for providing powerful traction, allowing the project to advance efficiently in complex terrain. Our forged bulldozer drive wheel(forged drive wheel for mining) uses wear-resistant materials and a rugged design to extend its service life and adapt to a variety of harsh environments. Our forged bulldozer drive wheel enhances transmission efficiency, reduces energy loss, and improves overall working performance. Our forged bulldozer drive wheel guarantees the stability and durability of the bulldozer through a reliable structure.

Heat treatment process:

Normalizing treatment of forged bulldozer drive wheel: eliminate the internal stress of the material, avoid deformation after processing, and ensure dimensional stability.

Quenching treatment of drive wheel for bulldozer: Improve the hardness and overall strength of the metal surface, enhance wear resistance, and extend service life.

Tempering treatment of drive wheel for bulldozer: Improve metal toughness, prevent cracking, and maintain a balance between high carrying capacity and impact resistance.

After heat treatment, the hardness range of drive wheel for bulldozer is controlled between HRC 28-34, which not only provides sufficient strength to support the traction needs of the bulldozer, but also avoids brittleness due to hardness.

Machining accuracy and inspection of drive wheel for bulldozer:

Cutting method: Plasma precision cutting is used to ensure the edge neatness and finish of the drive wheel for bulldozer, and to reduce subsequent wear and tear.

Mechanical properties testing: Use a universal tensile testing machine for tensile, compressive, fatigue and impact testing to verify the reliability of the drive wheel under extreme conditions.

Dimensional control of drive wheel for bulldozer: Through CNC machining centers, the high precision of the tooth spacing, rim thickness and installation position of the crawler drive wheel for mining is guaranteed, so as to achieve seamless matching and efficient transmission with the original vehicle drive system.

Crawler drive wheel for mining storage and storage:

1. Clean and then store: Before storing, the drag chain should be cleaned so that its surface is free of dust and dirt, just like the crawler drive wheel for mining needs to be cleaned regularly. The cleaned tow chain should be dried or dried to avoid storage in a humid environment to prevent mildew or corrosion. The same applies to mechanical parts such as crawler drive wheel for mining.

2. Avoid compression by heavy objects: If a heavy object is placed on the drag chain for a long time, this will cause the drag chain to be deformed if it is light and damaged if it is heavy. You can choose to place it flat somewhere or hang it on a shelf, similar to the design principle that crawler drive wheel for mining should avoid compression.

3. Avoid direct sunlight: The drag chain should be placed in a dry and cool place. Although the reinforced nylon material has a certain corrosion resistance function, care should be taken to avoid direct sunlight, otherwise crawler drive wheel for bulldozer will cause the nylon drag chain to age and affect performance and life, just as the crawler drive wheel for bulldozer requires sun protection to maintain durability.

About us:

Huayang has focused on the crawler drive wheel for bulldozer of crawler drive wheel for bulldozer for 10 years. We provide high-performance and high-compatibility drive wheels for construction machinery users around the world, which are widely used in various heavy-duty environments, such as construction, bridges, water conservancy, energy and port engineering. Fields. We also provide OEM and customized processing services. You can send drawings or specifications, and we will be responsible for the follow-up from material selection to final delivery. We are experienced in customized production and can flexibly meet your unique needs.